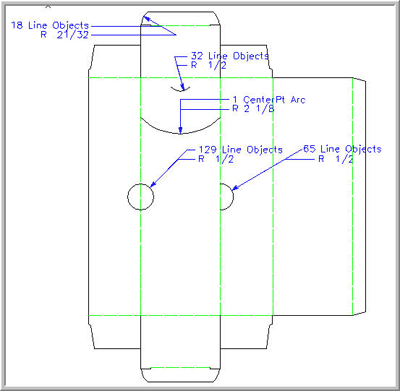

HPGL tech note: By default HPGL strokes arcs at five degree intervals. Rules™ can stroke the arcs, splines and ellipses as desired by adjusting the “Arc Radius Tolerance” to stroke arcs under a certain radius size. The amount of stroking is relative to the “Max Chord Length.” The smaller the tolerance, the greater the number of short line segments that are used to represent the arc. The majority of newer equipment will “curve fit” these small lines back into arcs in their own way. Sometimes you may want to manually “linearize” a curve. Use this command to break curves into a series of small, connected line segments that represent the curve. The drawing below shows a simple box design and the results of linearizing the design.

This function will run automatically when you send designs out as HPGL if you turn on that option in the Utilities → Rules Preferences.

Tolerance settings dictate how much linearization takes place when you use this function. The drawing above has an arc radius tolerance of 1”. This means that any arc or circle with a radius of less than 1” will be subject to linearizing. All curves over 1” are sent out as arcs or circles, whichever the case may be. This drawing also has a maximum chord length tolerance setting of .001”. This setting is the maximum allowable perpendicular distance of deviation from the original curve. The smaller you set this number, the more lines will be used to represent the curve and the curve will be “fit” more closely.

The drawing above shows the effects of linearizing this design with the tolerances discussed. Note that the one arc in the top center of the design is larger than our arc radius tolerance setting of 1” and did not get linearized. You can make some adjustments to the settings to suit your own style of design. If you use lots of small arcs as in designs for rotary die cutters, you may want to lower both tolerances until you find a setting that gives nice smooth curves to the sample maker.

Machines such as sample makers and lasers that use HPGL as their primary language vary in their application of the HPGL language. One machine might produce beautifully smooth curves and another jagged rough curves. Smoothness issues can be addressed by adjusting the settings for linearizing in Rules and/or adjusting the settings on your machine. If you’re on service contract, call or email us at AlphaCorr™ for in depth help with getting the best out of your machine using Rules.